Back

News

News

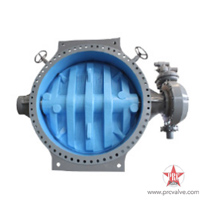

What are the problems of fluorine lined butterfly valve?

1. Due to the structural conditions, the structure is not suitable for making valves with diameters below DN200, because the overall structure of the valve plate is too thick and the flow resistance is large.

2. Because the multi-layer soft and hard laminated sealing ring is fixed on the valve plate, when the valve plate is normally open, the medium will form a positive scouring on its sealing surface, and the soft sealing belt in the metal sheet interlayer will directly affect the sealing performance after being scoured.

3. Due to the principle of fluorine-lined butterfly valve, the sealing between the sealing surface of the valve plate and the valve seat is to press the valve plate against the valve seat by the torque of the transmission device. In the positive flow state, the higher the medium pressure, the tighter the seal extrusion. When the medium in the flow path is countercurrent, the unit positive pressure between the valve plate and the valve seat is less than the medium pressure with the increase of the medium pressure, the seal begins to leak.

China Valve Media/Email:prcvalve@163.com

This site is the network editor reprint, the purpose is to convey more information, does not represent the network agree with its views and is responsible for its authenticity, such as copyright, content and other issues,pls contact this network within 30 days, we’ll delete the content in the first time.

[Statement], the copyright of articles on this site belongs to the original author, the content is the author’s personal opinion, only for reference and doesn’t constitute any investment or application advice. The website reserves the right of final interpretation of this statement.

Valve Horizon

Concentrating on Solution of Line Valves, Fujia Valve Settled into Display Platform of PRC Valve Media.

Fujia Valve Group cooperated with PRC Media in Feb. 2023, formerly settled into it’s Display Platform.PRC platform has set up a dedicated website for Fujia Valv...

Release time:2023/03/04

Fujia Valve Group was selected as the third batch of high-tech SMEs in Zhejiang Province in 2022!

Recently, according to the Administrative Measures for the Identification of Technological SMEs in Zhejiang Province, Fujia Valve was selected as the third batc...

Release time:2023/02/23

Material structure characteristics of fluorine lined stop valve

Fluorine-lined stop valve material1. Perfluoroethylene FEP (F46)Applicable media:Any organic solvent or reagent, dilute or concentrated inorganic acid, alkali, ...

Release time:2023/02/23

Personal

Personal