Back

Valve

Valve

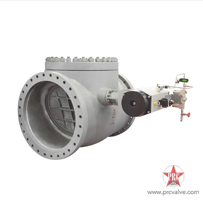

B series pneumatic actuator

Close

-

ZHE JIANG HUAERSHI ATUO-CONTROL INSTRUMENT VALVE CO.,LTD.

No. 15, Xingchao Road, Sidaoer Road, Binhai Park, Longwan District

No. 15, Xingchao Road, Sidaoer Road, Binhai Park, Longwan DistrictWarm Tips: If you need any more information, please send us mails at"prcvalve@163.com".

Personal

Personal

+86-577-8693 4111

+86-577-8693 4111