Assistant valve enterprise to win the world

Assistant valve enterprise to win the world

Release time:2023-02-25

Release time:2022-11-15

Release time:2022-08-11

Release time:2022-07-26

Release time:2022-07-26

Release time:2022-07-23

Release time:2022-06-11

Source

View count:1129

Source

View count:1129

With a history of 30 years, Beize has rapidly developed from a small family workshop to a "big" Beize with an annual production capacity of more than 300 million. This article takes you to read the secret

Clear objectives, focusing on butterfly valve production

Focusing on the long-term achievements, Beize has focused on the production of butterfly valves since its initial stage of business, and we are determined to provide customers with professional customized butterfly valve product with technical solutions.

"When I first entered the industry, I was engaged in the technical R & D and production of butterfly valves," Shao Liting, general manager of Beize valve, said in an interview. At that time, the domestic market was still dominated by low-pressure center line and double eccentric valves, but the quality was generally not high. President Shao found this situation and was committed to changing it. After the establishment of Beize, president Shao carefully researched and developed a series of butterfly valves that exceeded the market level at that time, such as triple eccentric all metal sealing butterfly valves, high temperature and high pressure butterfly valves, midline butterfly valves, double eccentric sealing butterfly valves, etc. Because of its strict production standards, the product quality is better, which has been highly praised by the market. At the same time, the products are exported to Europe, the United States, Russia, Africa, the Middle East, Japan, Southeast Asia and other countries and regions.

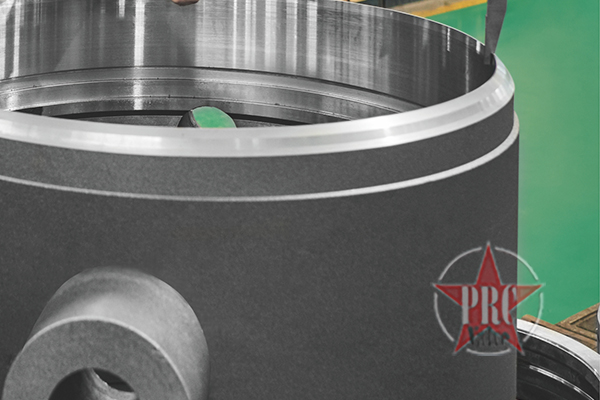

Today, Zhejiang Beize Valve Technology Co., Ltd. is a professional butterfly valve manufacturing company with its own brand "BZVF", specializing in the production of butterfly valves, but not limited to butterfly valves, it also involves four categories, including check valves, ball valves, gate valves and stop valves, with a total of more than 3000 varieties and specifications. It undertakes the manufacturing and production of valves below DN5000, which is suitable for harsh and complex working conditions such as high temperature, low temperature and high pressure. The pressure range is 150LB-2500LB and the wide temperature range is -196-700 ℃.

Beize has made achievements and won the title of "high-tech enterprise", but we are not complacent and stops at the moment. Mr. Shao led the company's R & D team to study the technical production of butterfly valves. There were 17 patents involving three eccentric valves only. Beize has continuously overcome difficulties, completed the upgrading of various series of butterfly valves, and produced butterfly valves with higher performance.

Recently, the R & D Department of Beize has combined the characteristics and advantages of four eccentricities to improve the high performance of the three eccentricity butterfly valve. The updated butterfly valve embraces small friction, small volume, light weight, high service life, good sealing effect, high cost performance and low operating torque. Moreover, the torque has been reduced by more than 50% on the original basis. The switch is flexible and light, and can be opened 1.5 million times.

"The independently developed new high-performance butterfly valve actually has been realized in foreign countries for several years, and due to limited technology, so it has not been able to realize in domestic production," Mr. Shao said. "Substituting the country for progress" is a high-frequency word in recent years. In response to the call of the nation, Beize valve set up a research and development team; searched for a large number of foreign data; understood the internal structure of this kind of butterfly valve and the applicable working conditions of major international users, and independently developed butterfly valves with the same performance. From importing by country to exporting abroad, Beize will continue to focus on the field of independent R & D and made in China in the future.

Planting planning increase production

The growth and development of the company can not be separated from reasonable layout planning. Beize has made clear strategy in the production direction of butterfly valves and made great efforts in plant planning.

Entering Beize, the plant area is reasonable, which makes it more tidy and standardized.

Implement the 5S site management of the plant, and make a reasonable layout for each area according to the production process, logistics and transportation requirements - shot blasting area, grinding area, warehouse, OEM area, CNC lathe area, assembly area, finished product area, welding area, material area, etc. During the layout of each area, the relationship between production logistics and production process shall be made clearly, and the layout shall avoid the possibility of cross trips, so as to ensure the orderly and efficiently production of Beize.

The layout of Beize plant strictly follows the principle of "safety first". Various production, prohibition and warning signs can be seen everywhere, so employees can see and keep safety in mind.

"It is better to check in advance than rework afterwards", "On-site process management and strict process factor control" and other prompt slogans can be seen everywhere in Beize plant. Beize develops a new quality objective control plan every year according to the needs. In 2022, Beize will divide the quality objectives into three parts for implementation - the first-time assembly pass rate of products, the on-time delivery rate of products and customer satisfaction, which are required to be ≥95%, ≥90% and ≥86% respectively. On this basis, Beize further decomposes the objectives of three plates. Taking the "one-time assembly pass rate of products" as an example, Beize requires that the pass rate of parts in machining process are ≥98%; the one-time assembly pass rate of products are ≥95%, the pass rate of valve performance test are ≥95%; the product error caused by the error of technical documents are ≤1%; the quality pass rate of castings / forgings purchased at one time are ≥98%, and the completion rate of training plan is 100%. Each responsibility shall be assigned to each department and each person. According to different projects, the accounting review shall be conducted monthly or annually, and the rewards and penalties shall be clear. Beize has always understood that punishment is not an end, but a means. We encourage employees to develop a culture of self-examination and self inspection, and put an end to such bad incidents.

Honor to hand with the answer sheet and "return to zero" for the exam. Shao Liting, chairman of Beize, said that the company's employees will maintain an "empty cup" learning attitude. Guided by the vision and goal of "paying attention to details and striving for perfection", Beize will "cooperate with each other by heart, and work together" to promote Beize to a new level.

[Source]: Zhejiang Beize Valve Technology Co., Ltd

[Author]: China Valve Media

[Editor]: China Valve Enterprise Style Editorial Department

China Valve Media/Email:prcvalve@163.com

Source:China Valve Media