Assistant valve enterprise to win the world

Assistant valve enterprise to win the world

Release time:2023-02-25

Release time:2022-11-15

Release time:2022-08-11

Release time:2022-07-26

Release time:2022-07-26

Release time:2022-07-23

Release time:2022-09-16

Source

View count:1476

Source

View count:1476

A Gate Valve, or Sluice Valve, as it is sometimes known, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. They are so-named because the part that either stops or allows flow through the valve acts somewhat like a gate. The gate is usually wedge-shaped. When the valve is wide open the gate is fully drawn up into the valve bonnet. This leaves an opening for flow through the valve the same size as the pipe in which the valve is installed. Therefore, there is little pressure drop or flow restriction through the valve.

Gate valves are sometimes used for regulating flow, but many are not suited for that purpose, having been designed to be fully opened or closed. They are used when a straight-line flow of fluid and minimum flow restriction are needed. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss. Gate valves are not suitable for throttling purposes. The control of flow is difficult because of the valve’s design, and the flow of fluid slapping against a partially open gate can cause extensive damage to the valve. Except as specifically authorized, gate valves should not be used for throttling.

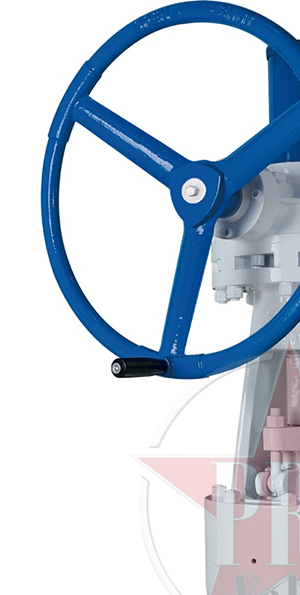

Gate valves are characterized as having either a rising or a nonrising stem. Valves with rising stems are used when it is important to know by immediate inspection whether the valve is open or closed and when the threads (stem and gate) exposed to the fluid could become damaged by fluid contami- nants. In this valve, the stem rises out of the valve when the valve is opened. Nonrising stems are used where vertical space is limited or underground. The stem is threaded into the gate. As the hand wheel on the stem is rotated, the gate travels up or down the stem on the threads while the stem remains vertically stationary. This type of valve will almost always have a pointer indicator threaded onto the upper end of the stem to indicate the position of the gate.

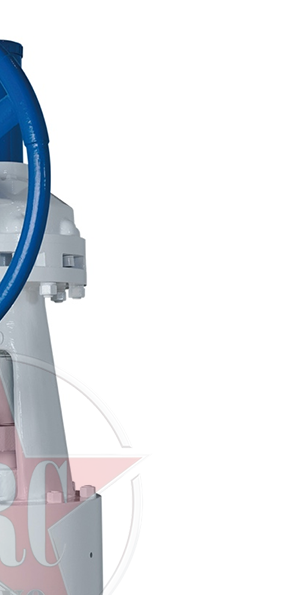

Bonnets provide leak proof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications. Another type of bonnet construction in a gate valve is pressure seal bonnet. This construction is adopted for valves for high pressure service, typically in excess of 15 MPa (2250 psi). The unique feature about the pressure seal bonnet is that the body - bonnet joints seals improves as the internal pressure in the valve increases, compared to other constructions where the increase in internal pressure tends to create leaks in the body-bonnet joint.

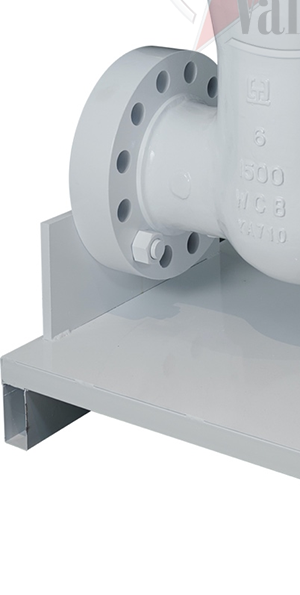

Gate valves normally have flanged ends which are drilled according to pipeline compatible flange dimensional standards. Gate valves are typically constructed from cast iron, cast carbon steel, gun metal, stainless steel, alloy steels, and forged steels.

Product reference photos are provided by Haogong Valve

China Valve Media/Email:prcvalve@163.com

Source:China Valve Media

Made in Zhejiang is recognized by the market and society, which based on regional brand, advanced standards, market certification, international recognition...

View count:2023/2/7

Recently, HaoGong Valve Co., Ltd. cooperated with PRC Media, formerly settled into it’s Display Platform. The platform built exclusive website for Jinhuili Valv...

View count:2022/9/27

Haogong valve was established in 2010 and settled in Wenzhou Binhai Industrial Zone. It is totally a young generation in Wenzhou where is famous for ...

View count:2022/6/23