Assistant valve enterprise to win the world

Assistant valve enterprise to win the world

Release time:2023-02-25

Release time:2022-11-15

Release time:2022-08-11

Release time:2022-07-26

Release time:2022-07-26

Release time:2022-07-23

Release time:2023-08-08

From:Ouming Valve Group

Source

View count:2135

Source

View count:2135

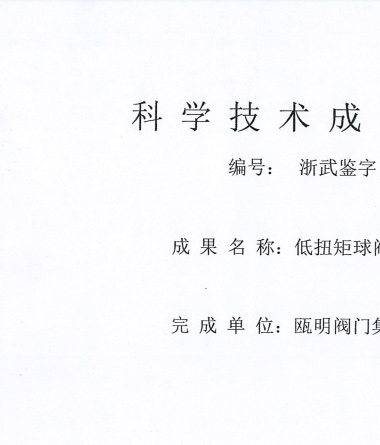

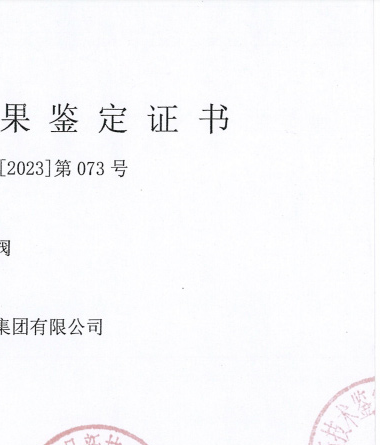

Recently, Ouming Valve Group has received identification certificates for new products, including low torque ball valves and non retention foot valves.

The research of "non retention foot valve" is that the support ring is fixed to the body and supports the ball. There is a drain tank in the support ring depression.When the ball cuts off the flow channel, a drain gap is formed between the drain tank and the ball. By inlet sealing structure, the drain tank equipped with the support ring at the outlet can discharge residual medium from the chamber while the valve the is closed, ensuring the cleanliness of the medium.

The research of "low torque ball valve" is that the ball protrudes with upper and lower fixed shafts.Both fixed shafts are equipped with bearings, and the body is equipped with upper and lower fixed blocks. Both fixed blocks are fixed to the body and form a bearing cavity for placing bearings.Fasten the ball through upper and lower double bearings, making the torque low.The ball will not be pushed towards the seat due to medium pressure,the friction force on the sealing surface will not increase, as well as the torque.

The gap between the outer diameter of the seat and the seat groove will not cause the seat to cling to the ball due to medium thrust, resulting in an increase in friction force on the sealing surfaceUnder low pressure conditions, the seat is compensated by an O-ring to seal the seat and the ball.The extrusion of the O-ring will not increase friction on the sealing surface of the seat.Therefore, this structure has extremely low torque, simple operation, and greatly reduces costs.The upper and lower double bearings are used to fix the ball. In the case of large pressure difference of the pipeline medium, the ball will not damage the outlet end seat due to the large thrust of the medium, resulting in leakage.The gap between the outer diameter of the inlet end seat and the seat box is large, which will not damage the inlet end seat due to high medium thrust.

China Valve Media/Email:prcvalve@163.com

Source:Ouming Valve Group